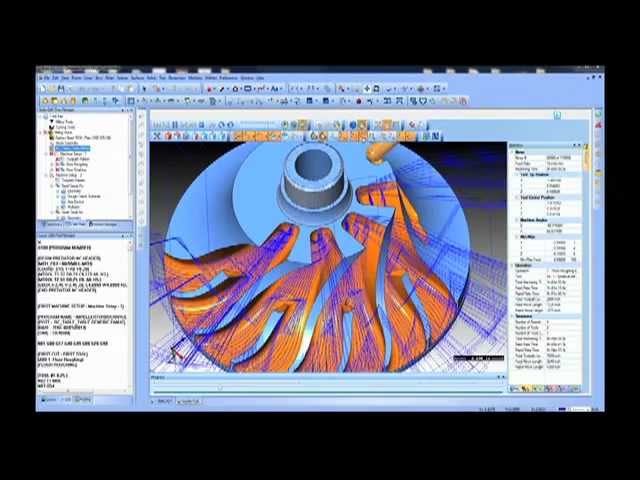

One of those teams – Roush Yates Engines – makes all of the Ford engines used in NASCAR using Mastercam. Mastercam’s strength is in production 2-axis and 3-axis machining, but it does offer 5-axis capability, and at least two of the NASCAR racing teams use Mastercam for their most sophisticated 5-axis machining – the porting of engine heads.

#BEST CNC CAD CAM SOFTWARE SOFTWARE#

The Feature Based Machining function in the X3 release can be used to automatically evaluate a part’s features and to design an effective machining strategy.ĬNC Software also says that the new X3 release offers substantially faster multi-axis toolpaths combined with enhanced control, and that they have developed new high speed toolpaths expressly for 2D machining that offer high speed cutting and hard milling, and also offer superior finish and longer tool life. Fully integrating Mastercam’s toolpath generation and editing functions into SolidWorks eliminated the need for shops that are familiar with SolidWorks to have to learn the idiosyncrasies of Mastercam’s CAD functions. SolidWorks is one of the most popular stand-alone 3D CAD packages used by machine shops and manufacturers. Mastercam’s X3 release also has become fully integrated with Dessault Systemes’ SolidWorks 3D CAD package. The six-year-old created toolpaths to machine a complex 3-axis part using the point and click functions. The new programming option is so simple and easy to use it was recently demonstrated by a six-year old daughter of one of CNC Software’s executives. With its latest release, X3, Mastercam now has Feature Based Machining and a simple check-thebox programming option. Mastercam has responded to the need to reducing learning time in two ways.

However, once they became familiar with it they also said they appreciate the power and flexibility the package gives them, especially in designing fixtures and work holding devices that never come with their customer’s part files. Thanks to this, the iterations of CNC programming become less time consuming, and comparing to other CAD/CAM software the CNC programming workflow itself becomes intuitive and clear.Even some long-time Mastercam users admit that it was not easy for them to learn to use the package.

#BEST CNC CAD CAM SOFTWARE HOW TO#

Using the result, the user can easily decide how to correct the parameters without switching to simulation or postprocessing. Immediately after the toolpath is calculated, SprutCAM performs the simulation in the background and shows the new state of the workpiece to the user in the same window.

This means that the CNC machine is 100% able to execute the generated program. The result of the calculation is not just the Cartesian points in abstract space it’s the actual positions of the machine axes required to reach these points. Kinematics and rest material consideration on every stepĪll the limitations of the machine model kinematics and the actual rest material that remains after previous operations and the fixture(s) geometry are used to calculate the toolpath. After that it’s easy to estimate the reachability of the surfaces when picking them for the machining. Before starting the programming, the user puts the models of the part and fixtures inside the virtual machine.

SprutCAM is a CAD/CAM software that takes into account the CNC machine model during the toolpath calculation.

0 kommentar(er)

0 kommentar(er)